- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

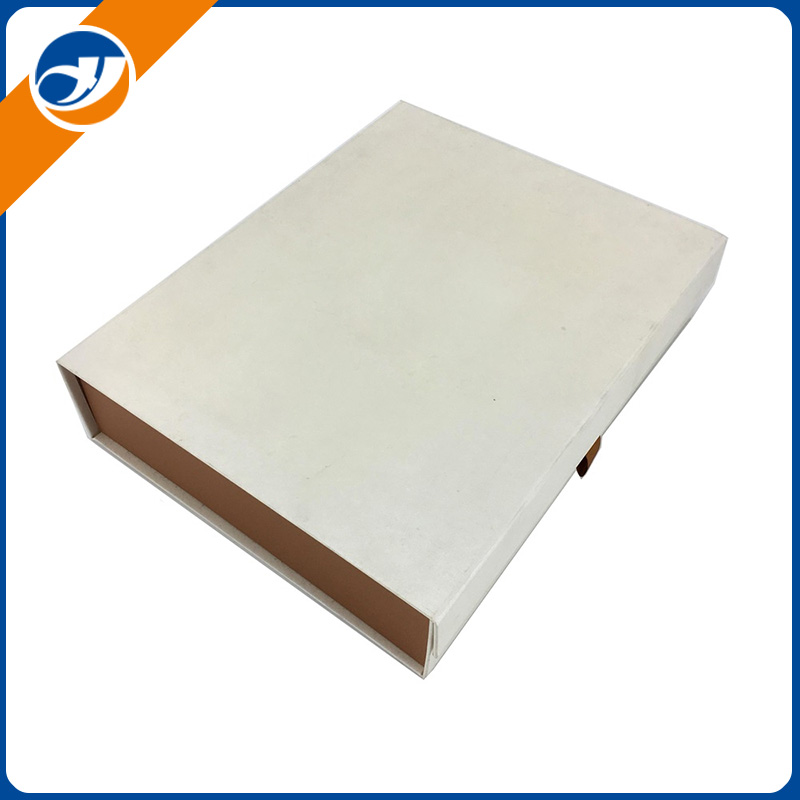

Top and Bottom Gift Box

Zemeijia is a professional top and bottom gift box manufactures and Suppliers from China. There may be a lot of top and bottom gift box manufacturers out there, but not all top and bottom gift box manufacturers are alike.

Send Inquiry PDF DownLoad

Zemeijia is China manufacturers and suppliers who mainly produces top and bottom gift box with many years of experience. Our professional expertise in manufacturing top and bottom gift box has been honed over the past 10+ years.

Custom Packaging supply Top And Bottom Gift Box For Hair Extension, Qingdao Zemeijia can custom top and bottom gift boxes with your own design. As manufacturer, Qingdao Zemeijia can save your costs at every way.

Top and Bottom Gift Box:

|

Size |

Customized Size |

|

Printing |

CMYK Color Printing |

|

Logo |

Customized Logo artwork |

|

Design |

Customer's Specific Requirement |

|

Artwork Format |

AI PDF PSD CDR |

|

Advantage |

POrofessional Design And Mockup |

|

Certificate |

SGS, ISO, FSC |

|

Sample |

Custom Printed Sample |

|

Lead Time |

10-15 Days |

|

Packing |

Master Carton |

|

Worldwide Delivery |

Customizable in Size And Printing. |

Top and Bottom Gift Box:

1. Food grade paper board , with or without PE coated inside are available

2. Can with or wihout PLA / PET / PE /OPP clear window

3. Customised design is welcome, flexo or offset printing avaliable

4. Can be custom print your company logo as your requested

5. SGS,FDA certificates, can directly contact with food, Eco-friendly

6. Will pack according to our standard export packaging

7. Export to all over the world. Welcome come to us.

Why choose us?

1. 100% Factory & manufactuer, saving your costs than buying from trading company.

2. Professional equipment and facility, such as advanced Printing & cutting machine.

3. Experiences designers and technician of packaging and printing aspect for various products.

4. Strict quality control system, make sure every piece of product to be 100% qualified.

5. With efficient management and high productivity, short delivery time within .

6. Near Sea Port and Air port, quite convernient for business and transportation.

Printing Works Process:

1. Typesetting and Composition

2. Copy Assembly and Process Photography

3. Image Carrier Preparation

4. Photomechanical Image Carrier Preparation

5. Light-sensitive Coatings

6. Photopolymeric Coatings

7. Diazo Coatings

8. Bichromated Colloid Coatings

Corrugated & Cardboard Box:

1. Pulping the pine chips

2. Making kraft paper

3. Shipping and storing the kraft paper

4. Corrugating the cardboard

5. Forming the blanks into boxes

6. Quality Control.

Top and bottom gift box surface treatment:

1. UV Spot: Ultra-violet cured coatings can be applied over ink printed on paper and dried by exposure to UV radiation. UV coatings can be formulated up to 100% solids so that they have no volatile component that contributes to pollution. This high solids level also allows for the coating to be applied in very thin films. UV coatings can be formulated to a wide variety of gloss ranges. UV coating can be applied via most conventional industrial coating applications as well as bysilkscreen.

2. Glossy finish: Art papers are one of the highest quality printing papers and are used for illustrated books, calendars and brochures. The grammage varies from 100 to 230 g/m2. These papergrades are triple coated with 20 - > 40 g/m2/side and have matteor glossy finish. Higher qualities often contain cotton.

3. Matt Finish: A dull finish or surface, as opposed to a shiny one.

4. Varnish: Resin dissolved in a liquid applying on wood, metal, or other materials to form a hard, clear, shiny surface after dry.

5. Foil Stamping: Typically a commercial printing process, is the application of metallic or pigmented foil on to a solid surface by application of a heated die onto foil, making it permanently adhere to the surface below leaving the design of the dye.

6. Embossing: The raising of paper and other non-metal products using specific tools to accomplish the task.